More specifically, 13 things we learned about GRF.

What is GRF? This is the Global Reporting Format for runway surface conditions. It came in back in Nov 2021, and if you have flown anywhere wintery since then, chances are you have encountered it.

The aim of GRF? To have one worldwide standard for how runway surface conditions are reported – to help make things a bit safer and reduce runway excursions.

A350 contaminated runway tests (credit: Airbus).

In Feb 2023, EASA held a webinar which involved a load of updates for various wintery airports on how GRF was going.

We listened in to the webinar. Here are the 13 things we learned…

1. SPWR means Specially Prepared Winter Runway

And it seems to be quite EU specific (we haven’t seen it in ICAO docs).

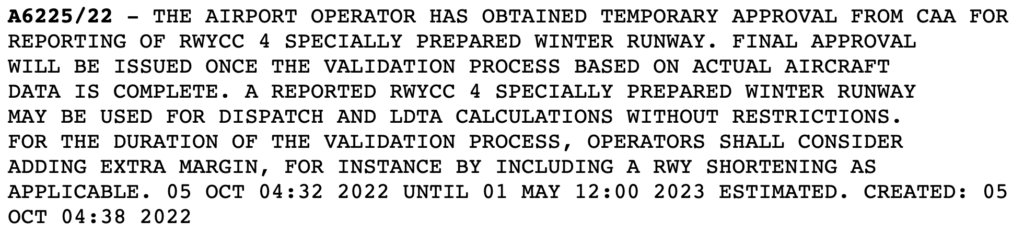

What it means: An airport where the temperature is -15 degrees C or below, and which is covered in compacted snow or ice can be treated (usually with sand) to improve the friction characteristics (how well you’ll decelerate). When it is done properly (and checked and approved) then authorities will designate it an SPWR and it will be rated RWYCC 4 (or possibly 3, but 4 is probably what you need in order to land on it).

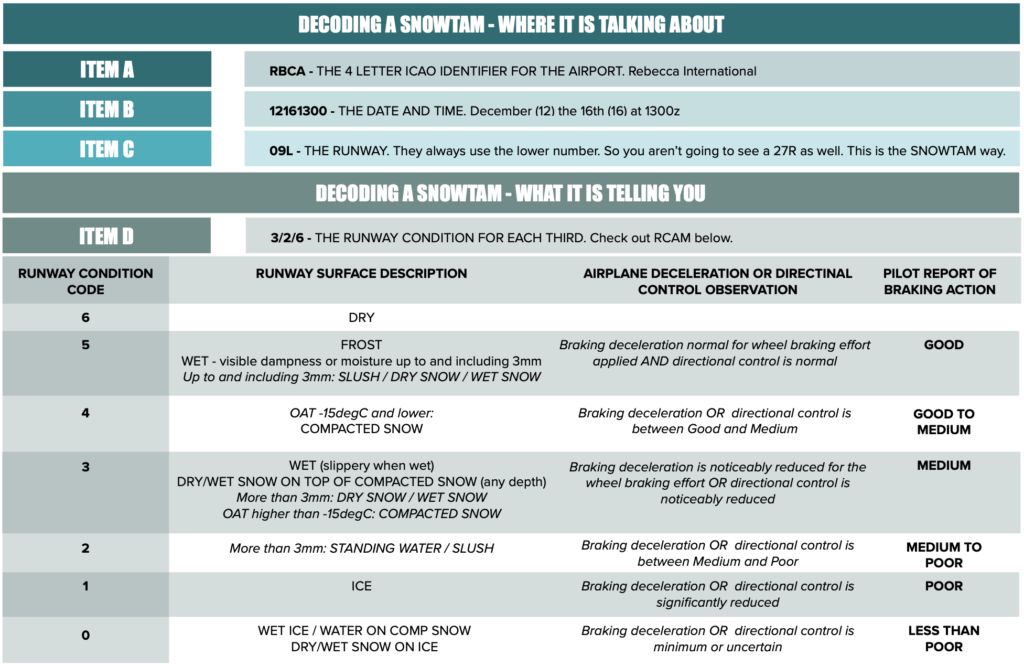

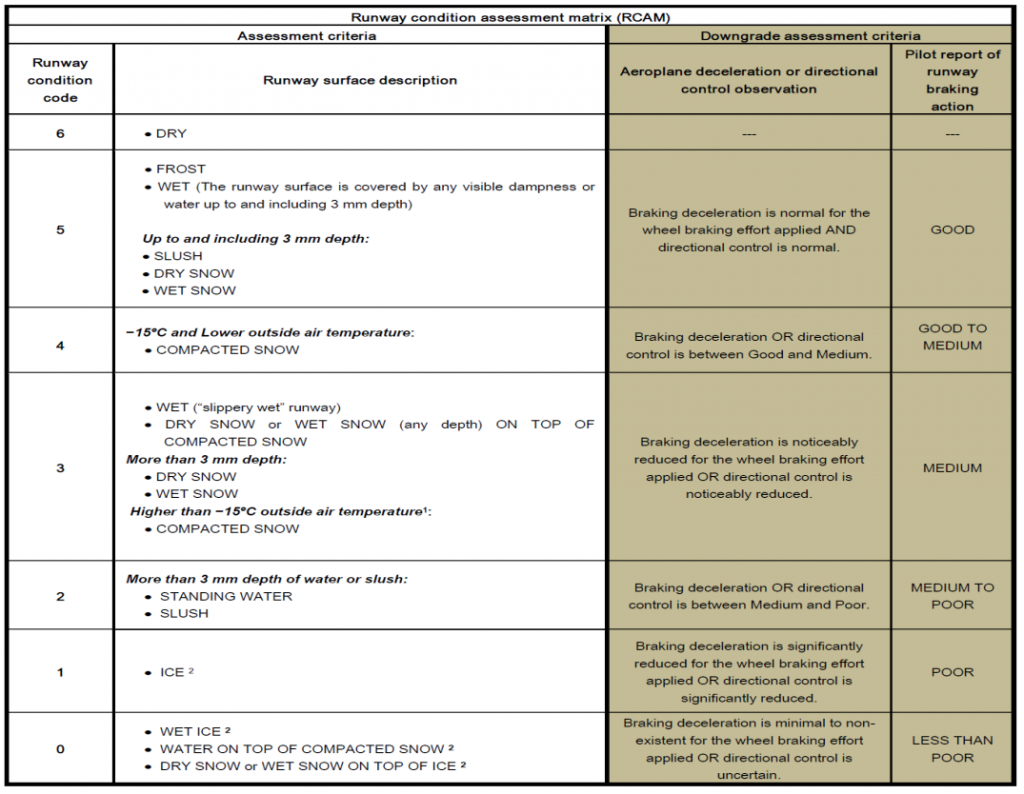

CC stands for condition code, 4 stands for a pilot braking action of good to medium, and an observed braking deceleration or directional control of good to medium on the runway condition assessment matrix.

2. Norway approved a bunch of airports for SPWR

It wasn’t easy, but they did it. The approvals were only temporary (most expire at the end of the Winter season in April/May 2023), but still, well done Norway.

What it means: You can expect more and more SPWR spots in winter zones.

3. The ATIS reports at airports giving GRFs can be really, really long.

What it means: If a runway was contaminated and then becomes Dry or Wet (so not contaminated anymore), they don’t necessarily cancel out the earlier report, which means all the info is going to be on the ATIS and that makes it really long (that’s what Norway said).

They are working on it. Trouble is, the other options are SNOWTAMs (these work, but how do you get an up-to-date one when you need it?) or ATC (clogs up the radio).

So for now, if you head somewhere wintery you can probably expect a pretty lengthy ATIS.

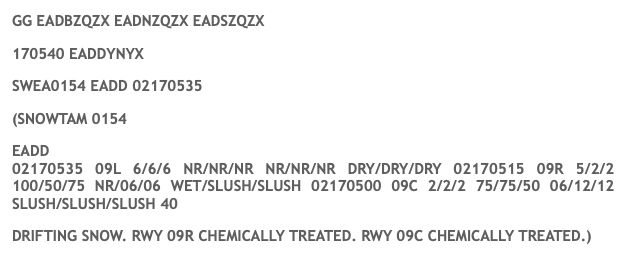

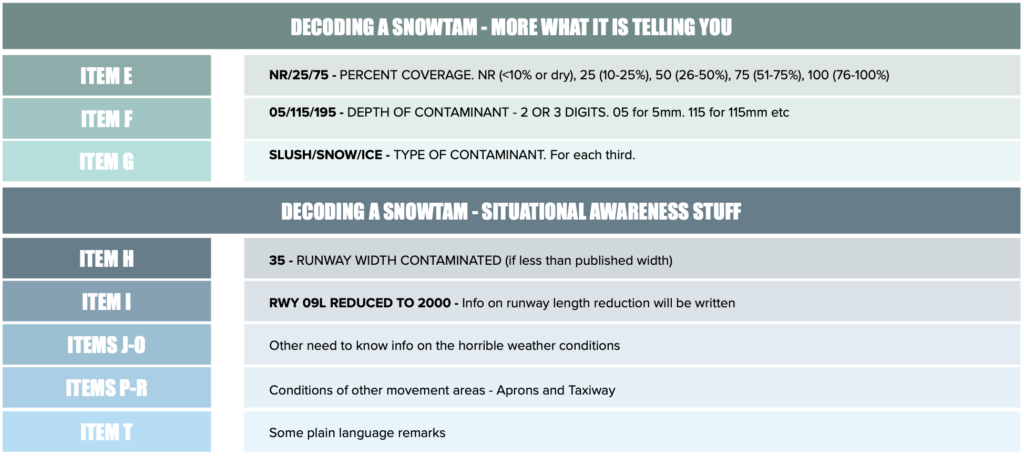

In case you’ve not seen it.

That was the top 3 things we learned. Here’s some more…

4. It isn’t easy for airports to be approved for SPWRs.

To get approval you need data, and to get data you need folk to be landing on the runway. But to land on the runway while it is treated you need approval…

What it means: You might still find yourself flying to airports next winter which don’t have their approval fully sorted. They issue temporary approvals, but until the data is in there may be some ‘uncertainty’ about the braking and directional control characteristics. But Norway got some done this year. Folk landed on them. It all went ok.

If you aren’t sure, talk to the airport authority to find out what they have, what they will report and what it means for you.

5. There is an airport in Norway called ENHV/Hooningsvåg

And it gets real wintery there.

What it means: 50% of landings in winter are on a contaminated runway, and the other 50% are on an SPWR. Oh, and their ‘winter season’ can be 50% of the year long. The same actually goes for a lot of airports in the upper latitudes so be prepared for winter ops and GRF if you head up there.

5. They are 95% confident in their GRFings.

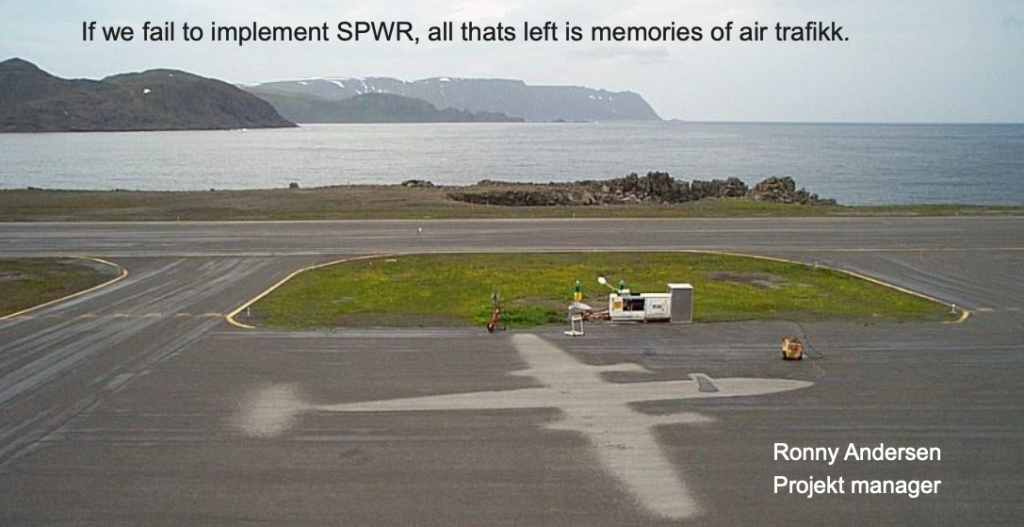

What it means: GRF works, even on SPWRs. Which is lucky because, according to Ronny Anderson:

OK, let’s see what folk outside of Norway have to say…

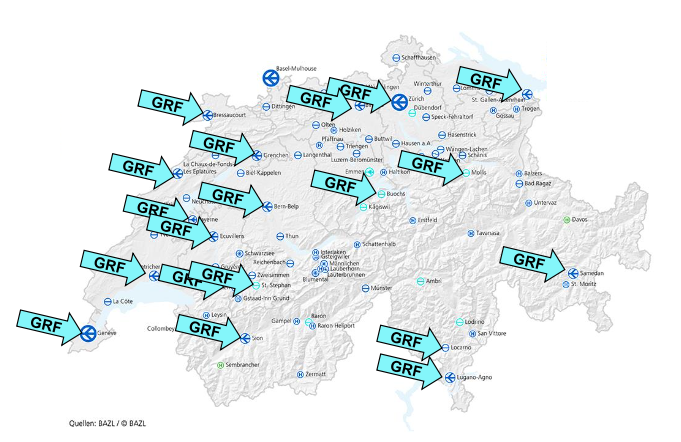

7: Switzerland also have a lot of runways using GRF.

19 in fact.

Here they are.

What it means: Well, they probably have long ATIS-es too. But also, GRF is supposed to be Global but we seem to be seeing it used predominantly at winter airports. Hmm…

8. Spain use it too!

They have 46 airports, and only experience what they call ‘soft’ winters – basically snow and ice isn’t that common, and actually rain is the biggest issue. In fact, only 20 of their aerodromes even have a snow plan.

What it means: They are probably pretty unfamiliar with handling snow and ice when it does occur… but also that GRF should be used anywhere you find runway contamination, which can mean rain too!

9. According to Spain, GRF doesn’t actually work very well for rain.

What it means: It means they discovered a bit of an issue with GRF when it comes to watery measurements… If there is 3mm or less of water then it is considered wet and the RWYCC is 5, but add just 1 more mm of water and you are in the standing water category and now the RWYCC drops to a 2.

Which is a problem? They think so, because measuring to that level of precision is difficult, detecting big changes quickly is difficult, and when they try it generally messes with their runway capacity because, presumably, guys are having to go and wade about the runway trying to measure a 1mm change in water level.

What that means: There is no solution right now that is entirely excellent, so there is a level of ‘subjective’ in the GRF you might experience when flying into wet runways anywhere in the world in fact (and you don’t want to be the first to discover that code 5 is actually a code 2 so be careful when hearing ATIS-es that talk about standing water).

Let’s hear something positive again…

10. Germany consider their GRF implementation a total success.

We say Germany, actually we’re talking about EDDL/Dusseldorf.

What it means: Well done them! We shall expect perfect runway condition reports whenever we operate there.

Not Dusseldorf. McMurdo station in Antarctica is a true ice runway (credit: Wiki Commons)

What are operators saying?

11. Crews need to understand the GRF works in runway thirds.

That means you use the lowest of the RWYCCs, you should check how much of the first third of the runway is ‘flared’ over, and should shorten the runway by a third if there is an RWYCC outlier (but always use an outlier crosswind).

What it means: Well, trying to calculate takeoff performance using GRF is not always easy because we don’t tend to work in runway thirds for it, and it isn’t necessarily clear how much ‘conservatism’ should be applied.

And then there is the fact you might only get an updated report just prior to takeoff which means trying to rework all your calculations under pressure.

What that means: There is probably some training to do with your crew if they aren’t totally familiar with GRF, and you should make sure what you put in your company manuals is clear and answers all these questions so they aren’t rolling down the runway thinking “Is this actually ok?”

12. Because GRF considers braking deceleration and directional control, it isn’t just the contaminant or surface condition that impacts this.

Downgrade and upgrade criteria need to be defined to include things like wind speed, precipitation, temperatures, various vehicle behaviours, etc etc.

Which means: If you operate in somewhere you need to really do your part reporting back. This has been in for a couple of years, but there are still some creases (ice ridges if you like) that need ironing out.

And don’t assume it is all spot on and a runway excursion will no longer be a possibility at a GRF using airport. This is a tool for improving safety only.

The 13th thing we learned about GRF:

We need to read up on it a bit more. If you do too, then here are some links:

- An old post we wrote on it

- A link to a PDF EASA made about it

- EASA’s actual page on it, complete with the regulations and a whole load of other presentations

- ICAO’s page on it (because it is global, not just European)